by Radiation Safety Institute of Canada | Apr 18, 2024 | Blog, News and Events

Fifty years ago, the uranium miners of Elliot Lake led by the United Steelworkers union, took a courageous stand for their health and safety. In an unprecedented wildcat strike, these brave men and women walked off the job in protest of unacceptable working conditions...

by Radiation Safety Institute of Canada | Mar 21, 2024 | Blog, News and Events

It is with great sadness that the Radiation Safety Institute of Canada (RSIC) shares with its friends, partners, and stakeholders the news that Ontario has lost a champion of justice and safety with the passing of Roy McMurtry, OC, OOnt, KC. Mr. McMurtry’s remarkable...

by Radiation Safety Institute of Canada | Mar 19, 2024 | Blog, News and Events

The Radiation Safety Institute of Canada (RSIC) is seeking individuals to serve on the Board of Directors for a 3-year term beginning in June 2024. Accountabilities The Board of Directors is responsible for setting strategic direction and providing stewardship to the...

by Radiation Safety Institute of Canada | Oct 3, 2023 | News and Events

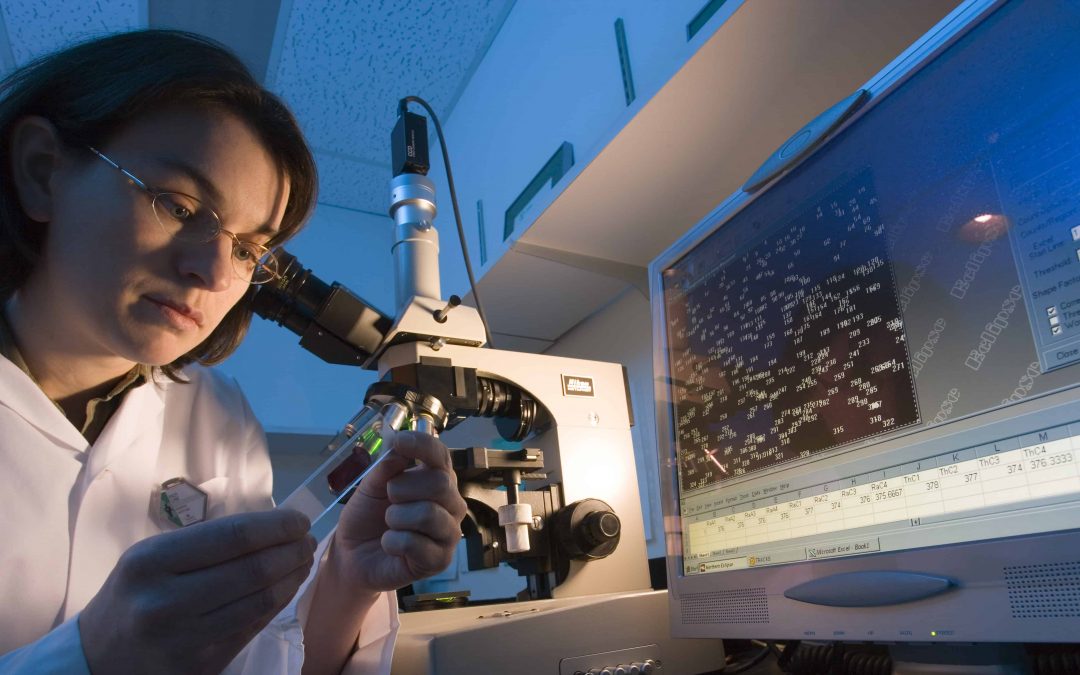

In Ontario, workplaces who use x-rays under 1 MeV for uses other than for human health care must register their equipment with the Ministry of Labour, Immigration, Training, and Skills Development. The Radiation Safety Institute of Canada has recently developed a free...

by Radiation Safety Institute of Canada | Jun 23, 2023 | News and Events

With much appreciation for his contribution to the work of the Radiation Safety Institute of Canada and its Board of Directors, we announce the retirement of Tim Armstrong Q.C., O. Ont. From the RSIC Board as of June, 2023. While stepping away from an active Director...

by Radiation Safety Institute of Canada | Mar 30, 2020 | News and Events

TORONTO, ONT. — Tim Armstrong, Chair of the Board of Directors of the Radiation Safety Institute of Canada, is pleased to announce two leadership changes at the Institute. As of April 1, 2020, Dr. Reza Moridi will take over as the Chair of the Board of Directors,...